Posted on :- 12 Feb 2025

Description

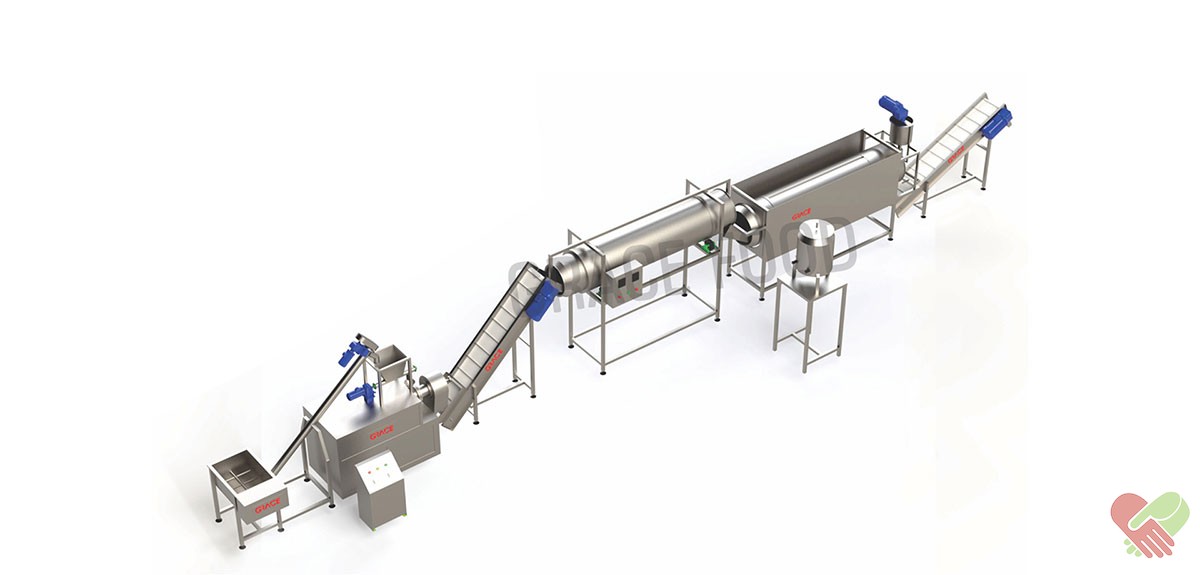

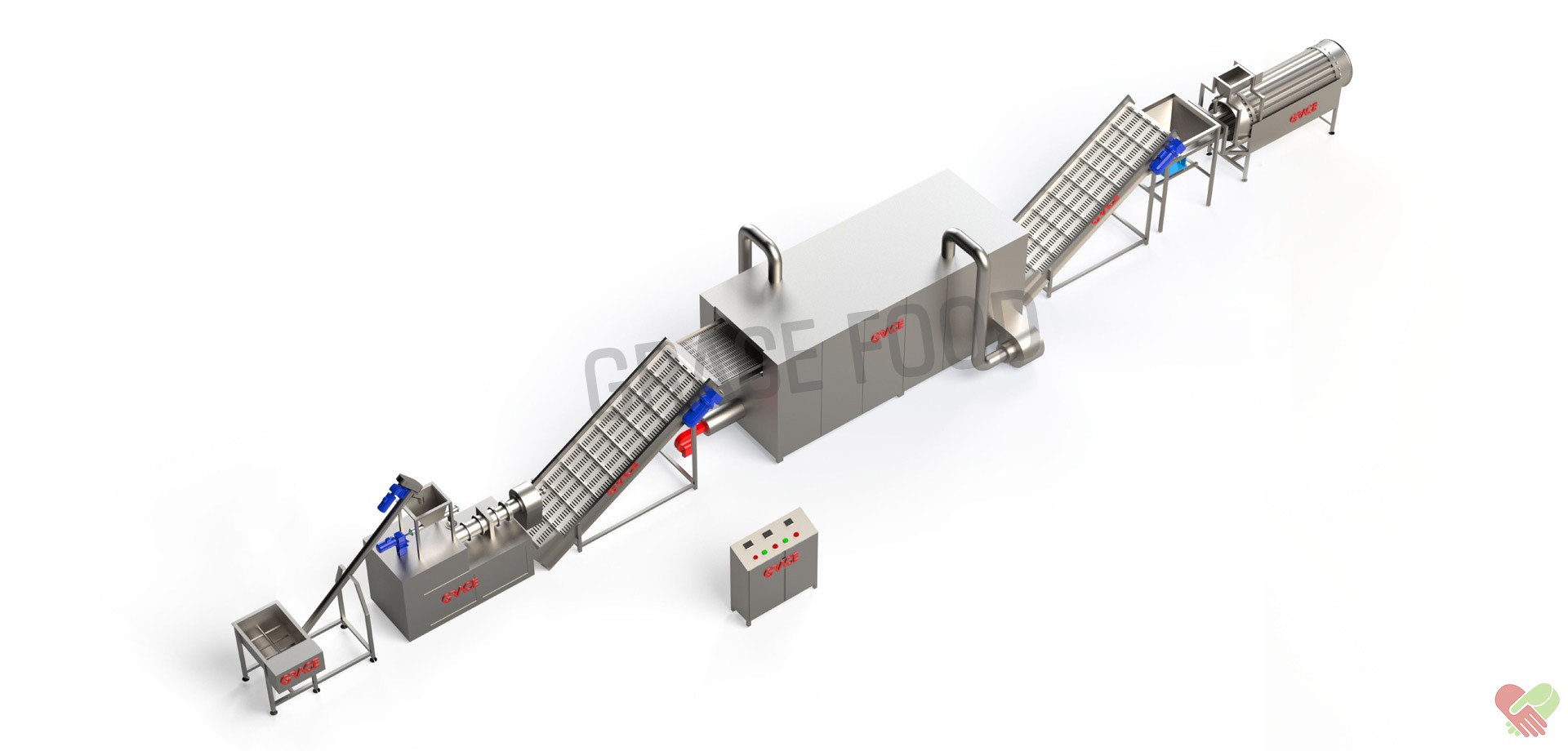

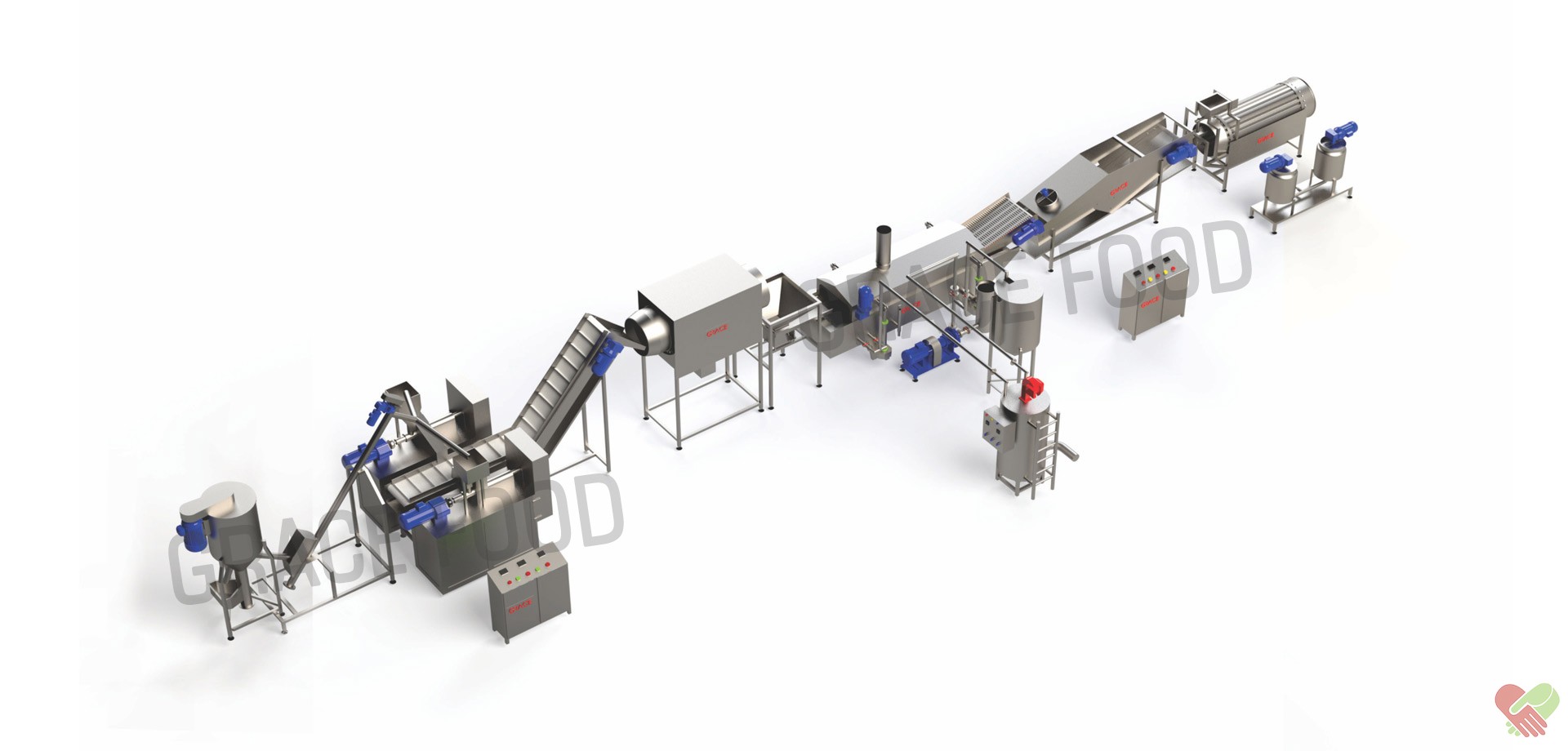

The principle of auger filler is to dose the product by auger screw. Auger screw speed & rotation is controlled precisely by servo motor. Auger filler is used mainly for sticky powders like milk powders, flours, ground spices, coffee powders, pesticides, etc. Auger filler system includes a hopper containing product to be packed. The product level is maintained using inclined or horizontal screw conveyor. There is an agitator, which churns the material & helps to break lumps. The pitch of auger screw is filled with the material, when it rotates & the same is discharged to the bottom of the bag to be formed. Features Servo Driven for high efficiency & accuracy. Precise & accurate dosing. Integrated with bagger through network. Works in synchronization with bagger speed. Can work with close loop system, if attached with check weigher as an option. Rugged construction ensuring consistent high dosing accuracy. All contact parts made out from stainless steel 304. Fast & easy cleaning agitator hopper design. (APPROX PRICE)

Specification

| Mfg. By / Brand Name | PACE PACKAGING MACHINES. |

| Year of manufacture | 2025 |

| size | - |

| power | - |

| Weight | - |

| location | Ahmedabad, Gujarat, India |

| Machine type | - |

| Seller type | - |

Service provider

| Service provider | N.A. |

| contact number | N.A. |

Other Ads by Seller

Similar Ads